CELL MANUFACTURING EQUIPMENT

Automation solutions to meet cylindrical, prismatic, pouch cell production from different customers requirements.

Cell Manufacturing

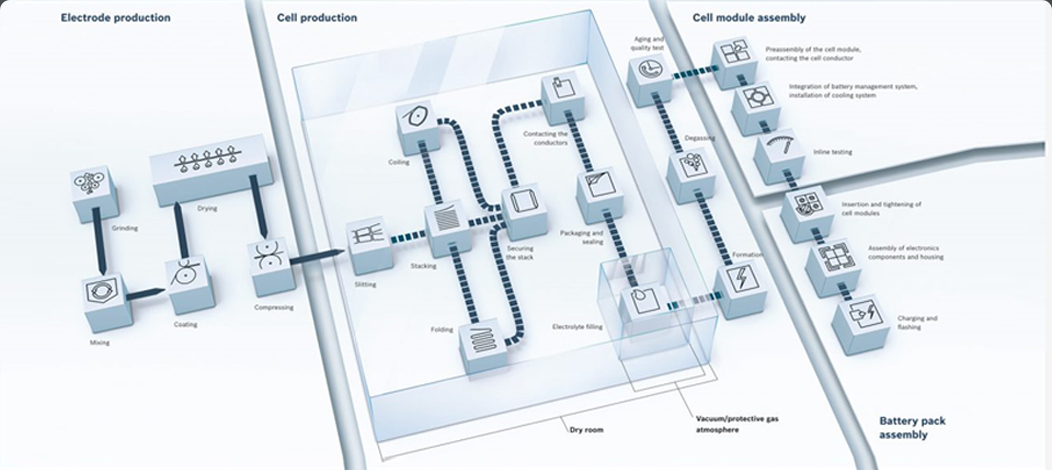

THIS IS A FLOW CHART

CELL FORMATION&GRADING TESTING

CELL FORMATION&GRADING TESTING  CELL ASSEMBLY

CELL ASSEMBLY  CELL FORMATION&GRADING TESTING

CELL FORMATION&GRADING TESTING  CELL MAKING PROCESS

CELL MAKING PROCESS